The Highest Quality

THE BEST IN METALS MANUFACTURING

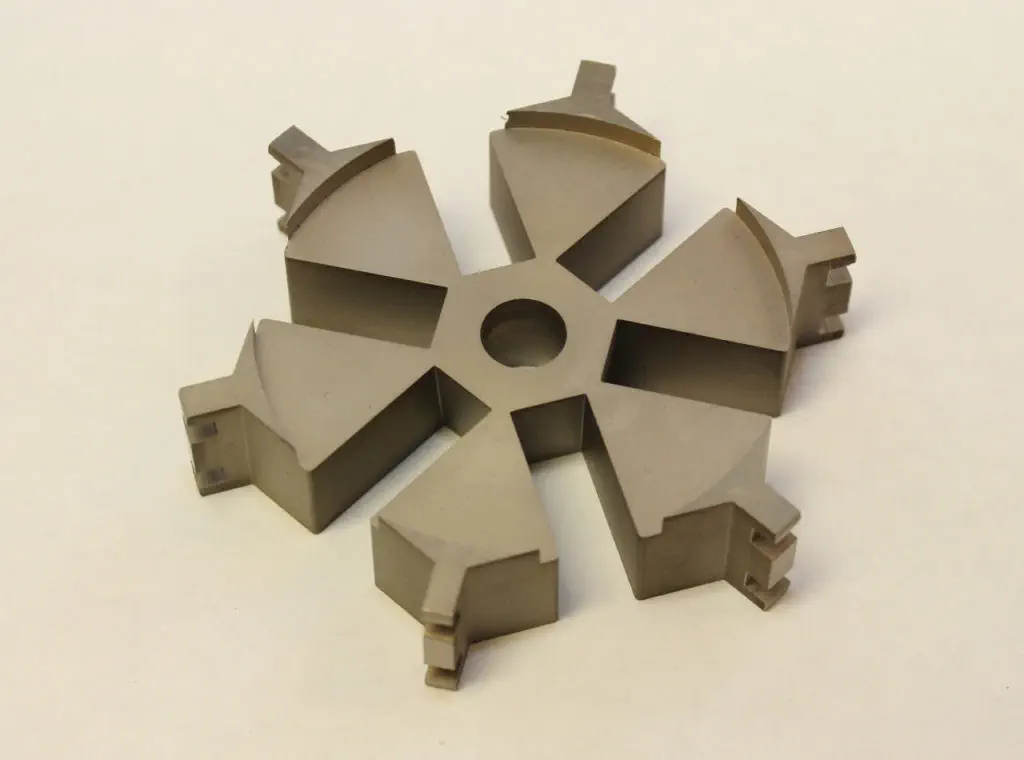

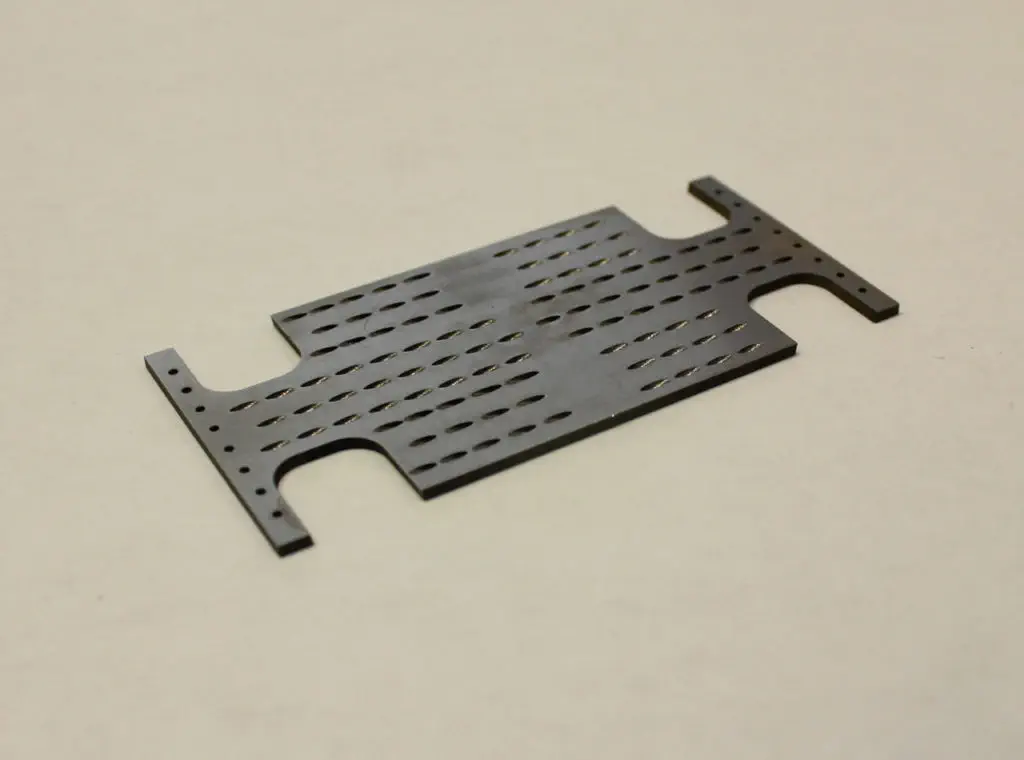

ARC EDM, Inc. DBA Cutting Edge Wire EDM, is a manufacturing company specializing in the production of precision machined components using high-reliabilityand high-performance FANUC Wire-cut Electric Discharge Machines and Omax Waterjets.

Our Mission

Built on a foundation of hard work and dedication. Our mission is to maintain the highest level of integrity in all interactions and produce components of the highest quality possible that we can be proud of.

READ MOREWHAT WE DO

A Selection Of Industries We Serve

Our network of talented, and trustworthy manufacturing professionals can help you quickly, and cost-effectively realize your dream project. We can create custom part prototypes from the design phase, clear through final production.

Realize your dream project.

THE BEST IN METALS MANUFACTURING

THE ADVANTAGE

Our Facilities

We house some of the best equipment in the wire edm and waterjet industries in our facilities.

Check out our equipment.