EDM

WHAT WE DO

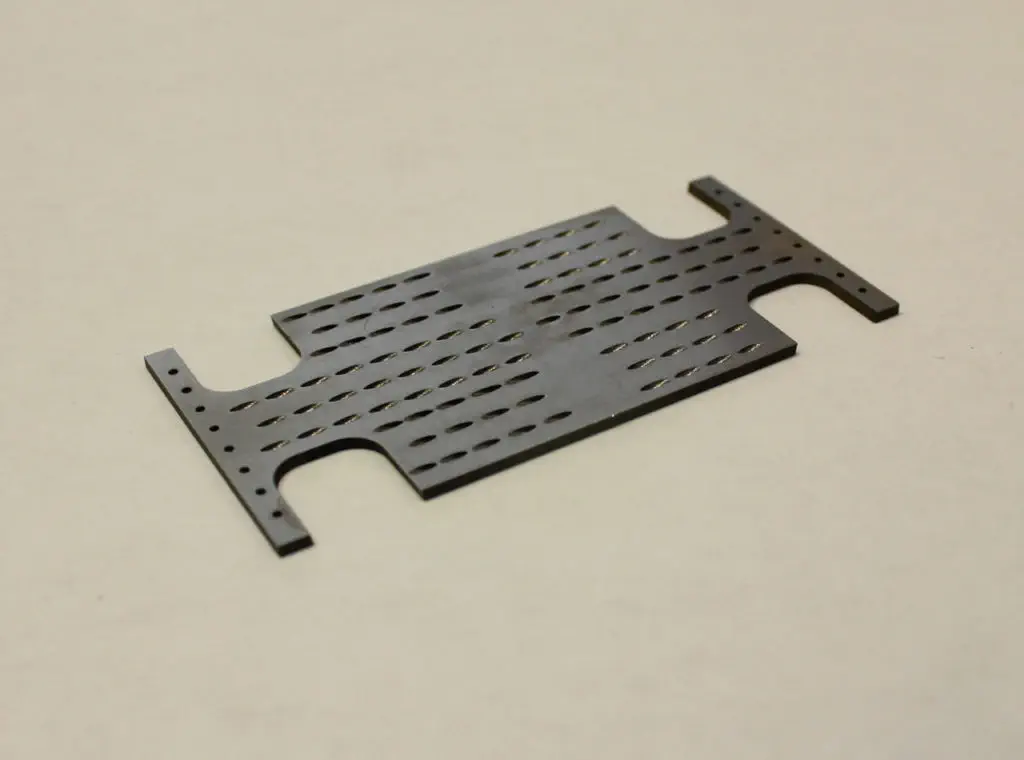

Wire EDM

Wire EDM machining on material up to 16 inches thick

Machining of all steels, carbide, and aluminum 15.7″ x 23.6″ table travel We machine parts up to 16″ thick Wire diameters from 0.004″ to 0.012″ 4 Axis Programming

What is Electrical Discharge Machining (EDM)?

Electric discharge machining (EDM), is a manufacturing process whereby an object is manipulated using electrical discharges (sparks). Material is removed from the workpiece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage.

When the distance between the two electrodes is reduced, the intensity of the electric field in the volume between the electrodes is expected to become larger than the strength of the dielectric, and therefore the dielectric breaks allowing some current to flow between the two electrodes. A collateral effect of this passage of current is that material is removed from both the electrodes.